17

© 2003 Templex Inc. . 3 Stanley Ave. . Thomasville, NC 27360 USA . Tel: 336-472-5933 . Fax: 336-472-5944 . www.Templexinc.com . E-mail: Sales@TEMPLEXINC.COM

COMPRESSED AIR CONSUMPTION FOR TEMPLEX WASTE REMOVAL SYSTEMS

GENERAL INFORMATION

CFM = Cubic feet per minute

LPS = Liters per second

LPM = Liters per minute (LPS x 60 = LPM)

1 CFM = 28.3 LPM (.47195 LPS x 60 = 28.3 LPM)

PSI = Air Pressure- Pounds per square inch

1 PSI = .06895 Bar,

Example: 80 PSI = (.06895 x 80) = 5.5 Bar

The air consumption for chain removal only will be the same for a Templex Dual Chain & Waste Removal System. Always use a Templex

Patented Dual Chain & Waste Removal Vacuum Assembly when vacuum is needed for both a chain cutter and trimmed waste removal to

conserve compressed air.The Templex chain removal vacuum and the dual chain and waste removal vacuums operate best at 80 psi or

5.5 bar. Compressed air consumption will vary from machine to machine depending on air pressure, flow control adjustment,

weight of fabric, thread, and actual sewing cycle.

EXAMPLE 1: 40 overlock/safety stitch machines sewing a light weight to medium weight knit or woven fabric using

T-150 texturized poly or 100s/2 cord spun polyester thread.

AIR PRESSURE: 80 psi or 5.5 bar.

SEWING CYCLE: 50% to 60%

FLOW CONTROL ADJUSTMENT: opened counter clockwise one mark on Treadle Rod Air Switch.

CFM used Per Machine (approximate) = 2 to 2.5 cfm. CFM total: 2.5 cfm x 40 machines = 100 scfm

Compressor Recommendation: Minimum of 25 HP Screw Type (100 Total cfm ÷ 4 = 25 HP) or minimun of 35 HP Piston Type (100 Total

cfm ÷ 3 = 35 HP). Consider next compressor size up to allow for future needs.

EXAMPLE 2: 30 overlock / safety stitch machines sewing a heavy denim fabric using a 40s/3 cord cotton thread.

AIR PRESSURE: 80 psi or 5.5 bar

SEWING CYCLE: 70%

FLOW CONTROL ADJUSTMENT: opened counter clockwise two marks on Treadle Rod Air Switch.

CFM used Per Machine (approximate) = 3.5 to 4 cfm. CFM total: 4 cfm x 30 machines = 120 scfm

Compressor Recommendation: Minimum of 30 HP Screw Type (120 Total cfm ÷ 4 = 30 HP) or minimun of 40 HP Piston Type (120 Total

cfm ÷ 3 = 40 HP). Consider next compressor size up to allow for future needs.

IMPORTANT!! These are estimates and may vary depending on proper installation and size of main air supply trunk line, altitude, proper

installation of Templex waste removal products, and percentage of pressure drop when vacuum is activated

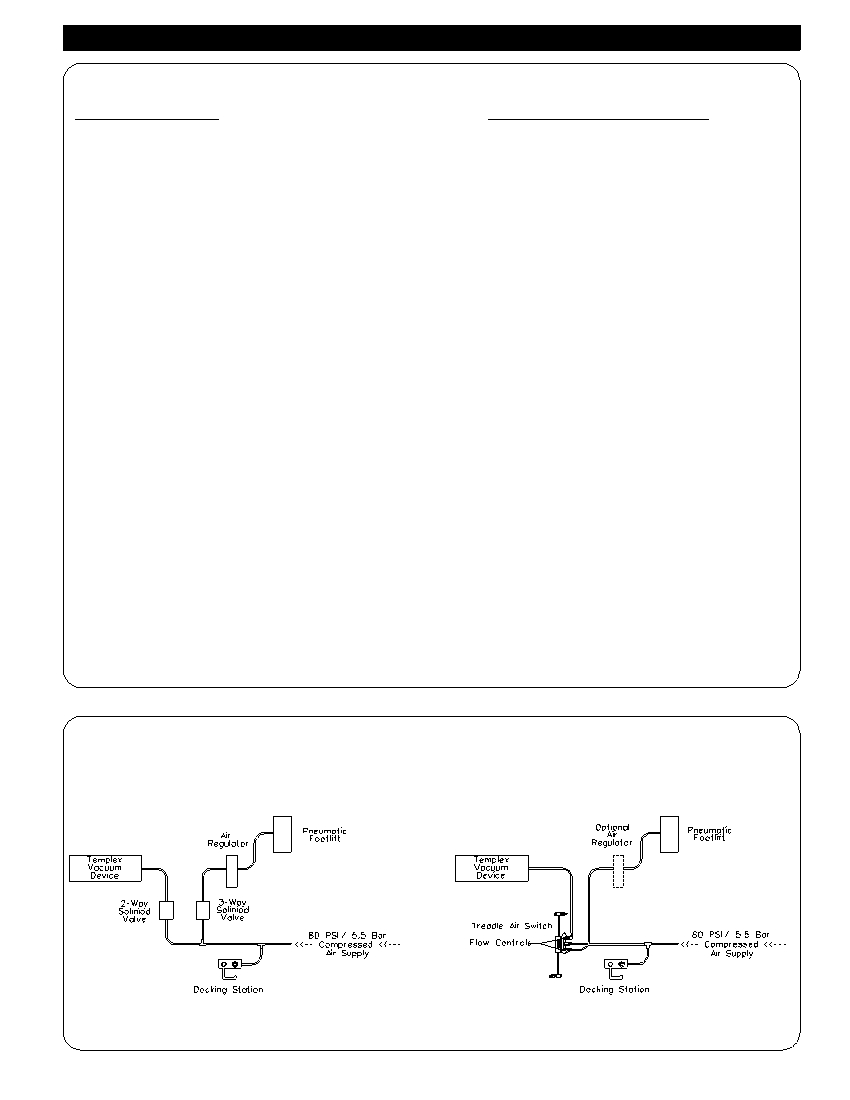

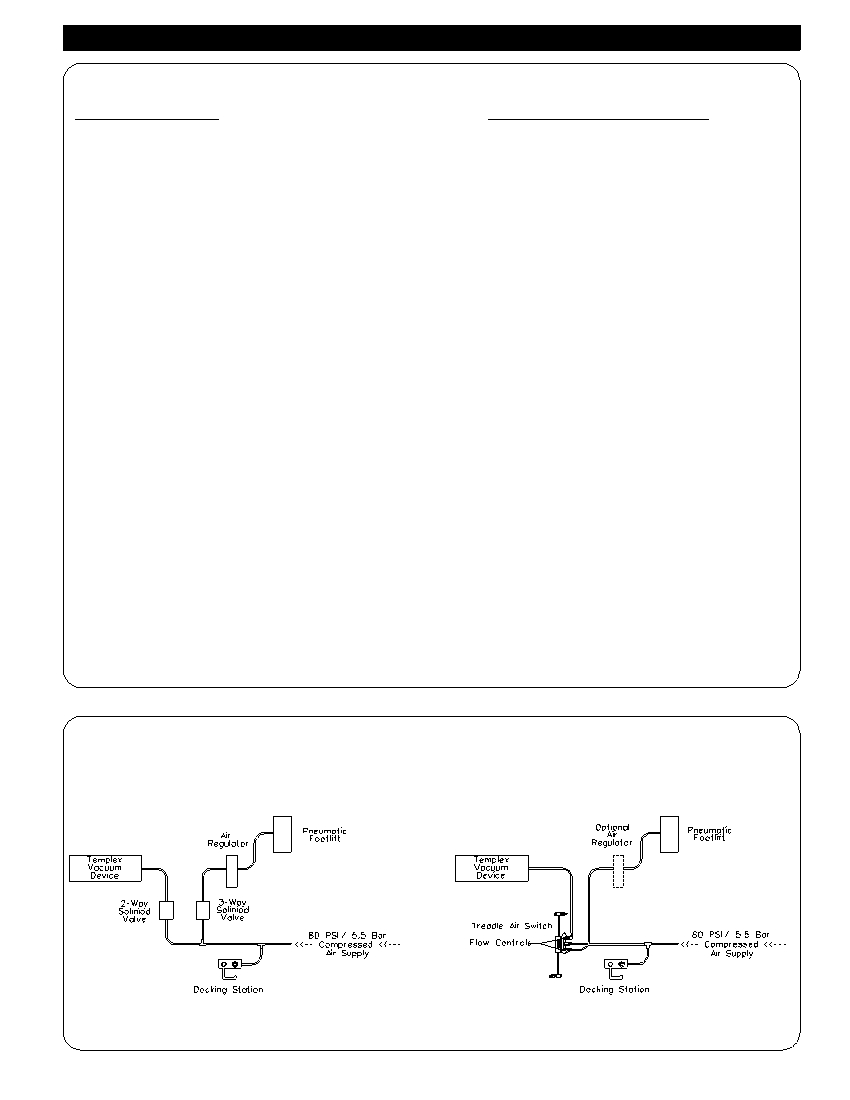

COMPRESSED AIR CONNECTION DIAGRAM

Proper pneumatic connections using

Proper pneumatic connections using

24 volt DC solenoid valves.

a Templex Lite Touch Treadle Rod Air Switch.

Note: A 3-way solinoid is necessary to

Note: Use of a filter regulator is not necessary when using a

operate a single acting air cylinder

Templex Lite Touch Treadle Rod Air Switch with built in flow controls

TYPICAL AIR COMPRESSOR CAPACITY

Piston Type: Each 1 HP Generates approximately

3 SCFM or 84.9 LPM

Screw Type: Each 1 HP Generates approximately

4 SCFM or 113.2 LPM

Example: A 25 H.P. Screw Type air compressor will

produce 100 SCFM or 2830 LPM (liters per minute) (25hp

x 4 scfm) = 100 scfm or (25 hp x 28.3 lpm) = 2830 LPM.

TECHNICAL INFORMATION